Grade Crossing Protection

Pintsch grade crossing warning systems are a superior choice for many railroad signaling applications. Axle counting technology offers immunity to many shunting sensitivity issues, such as rusty rail, contaminated ballast, electromagnetic interference, and traction power related problems.

Pintsch axle counting systems also minimize maintenance issues. Because the train detection method provides a high degree of isolation from the rail, lightning ingress is minimized. Multiple layers of redundancy in the control and relay topology eliminate relay testing. Sensor cables are monitored continuously for major changes in electrical characteristics. A signal maintainer can instantly observe the status of all major control paths within the train detection system, all of which are displayed on the front panel.

Pintsch axle counting systems are ideal for complex grade crossing systems, such as at roads that penetrate yards or other multi-track crossings. Approach circuits can also be programmed to time-out or detect switching movements, thereby minimizing disruption to vehicle traffic when cars are stored in an approach or when trains stop and reverse direction in an approach circuit

Basic Functions of Pintsch Tiefenbach Grade Crossing Technology:- A fail-safe, virtual track circuit is created using proven Pintsch double wheel sensors. When combined with suitable evaluation methods, these sensors can be used to determine the presence of passing wheel flanges, note direction, and increment or decrement a counter. When more than one axle is present in a circuit, the protected zone is determined to be occupied.

- A vital control topology ensures the highest level of safety. Two primary activation paths are present, one of which functions on a direct path from the sensor amplifier module to the relay release card controlling the crossing signal network, and a second of which functions via the counting circuit. Within each of these circuits are multiple layers of redundancy. In fact, there are more layers of redundancy in a Pintsch axle counting system than one finds in modern aircraft control systems.

- Relays operate both redundantly as well as in anti-valent fashion. In other words, for each train detection function, more than one relay is controlled, and, in addition, anti-valent relays must also function simultaneously. These control circuits are mechanically and electrically interlocked to ensure the highest level of safety. It is for this reason that Pintsch systems are used for the world’s highest speed passenger train corridors.

- Any crossing configuration is possible from basic long islands to approach-island-approach configurations, and complex track layouts. Switches are also easily accommodated without additional infrastructure and its associated maintenance issues.

- Manual activation for specialized purposes is also available via a key operated switch at front panel, as are both local and remote reset options (with an appropriate safety plan).

- An event recorder retains a detailed log of activation times, axle counts, and similar data to limit the railroad’s liability in the event of an accident.

- Pintsch offers a remote monitoring service, with regular monitoring and remote diagnostics, thereby facilitating predictive maintenance and advanced remote customer support.

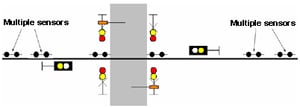

Standard Approach-Island-Approach Track Layout

Constant Warning Time Track Layout

- The control system is modularly structured. This ensures a lower-cost basic setup for single-track sections as well as the ability to easily expand the system for as many tracks as necessary.

- The sensor technology (double wheel sensor) is maintenance free and unaffected by all known sources of interference (e.g. traction reverse currents, rail braking, high voltage catenary lines, RF interference, etc.

- The control system is designed for installation in relay cases in all environments, from arctic conditions to tropical zones.

- Axle counting techniques are not subject to ring-through, intermodulation problems, or other characteristics affecting predictors and motion detector technology.

- Axle counting is an ideal solution for track circuit overlays. An axle counting system can be installed atop any existing track circuit without concern about interaction.

- Axle counting systems are ideal for island circuit replacement in northern climates where highway grade crossings are affected by snow-melting chemicals.