Rail Sensors | Inductive Proximity, Magnetic and Level Switches

This is our motto. We represent innovation, safety and efficiency. Our system solutions are customised, individually dimensioned and match precisely the respective requirements. With our products we focus on:

- Signalling technique

- Shunting equipment

- Sensor technology for industry and mining

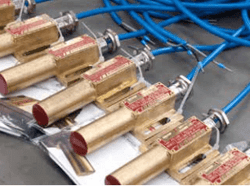

In comparison to sensors available in the market, the inductive proximity switches, magnetic switches and filling level monitors (level switches) by PINTSCH TIEFENBACH feature a unique ro- bustness and long service life even in areas with extreme envi- ronmental conditions. Examples are: sensors in hot-rolling lines and presses in steel works as well as in deep coal mining or in the chemical industry, where - in addition - requirements with regard to intrinsic safety and explosion protection must be met. The basis for the development of these components was the early activity of the company as a special equipment provider in deep coal mining and the experience gained therefrom. Due to an application-related intensive consulting in connection with the provision of supplemen- tary assemblies for the evaluation of the sensor signals, the users profit from this knowledge and find the optimum solution for their application case

- Contact-free actuation thanks to permanent magnets

- Maintenance-free

- High rupturing capacity

- Wide temperature range

- Suitable for any installation position

- High responsiveness up to max. 30 m/s

- Long service life of 109 switching cycles

- Virtually no inertia

- With cable set or cable compartment

- Cable lengths of 2 m, 5 m, 10 m, 15 m etc

- Cable:

- standard Ölflex (oil-resistant),

- silicon (temperature-resistant up to 180 °C),

- Purwil (UV-resistant)

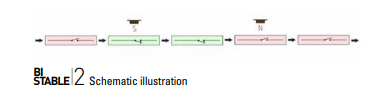

The switches are used as magnet-sensitive, non-contact pulse and latching switches.

Components and mode of functioningThe magnetic switches consist of cast-resin insulated inert gas contacts that are integrated in a corrosion-proof switch housing. By moving a magnet passed the switch the contact closes or opens. During the closing procedure the magnetic field increases in a square progression while the gap between the contact studs becomes increasingly smaller and then the contacts close with snap action. Due to the small distance between the contact studs and their low mass the contacts are switched with virtually no inertia.

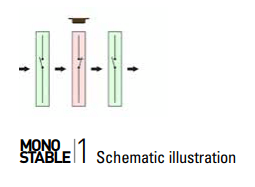

Pulse switch (monostable)In this switch design the switch is actuated for as long as it is influenced by the magnetic field. When removing the magnet the switch returns to its resting position.

In this switch design the switch is actuated for as long as it is influenced by the magnetic field. When removing the magnet the switch returns to its resting position.

If the switch is arranged on a ferromagnetic material, the switching distance is reduced because while the actuating magnet moves towards the switch the magnetic lines of force are distorted or short-circuited. If, in contrast, the magnet is arranged on a ferromagnetic material, the switching distance increases because the effect of the switching pole and thus the entire magnetic field are increased.

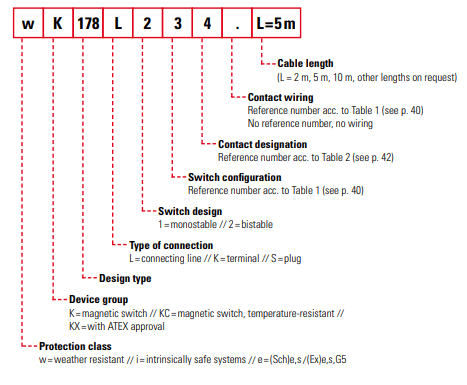

Type codeOrder example wK178L234.L = 5 m