Pintsch NA Railway Wheel Sensors | Inductive Wheel Sensors

- Axle Counting

- Switch control

- Yard automation

- Speed measurement

- Red-light overrun

- Positive train control

- Contact-free sensing and activation by the wheel flange present.

- Maintenance-free and extremely durable.

- Mounting through web of rail or clamp.

- Water-resistant.

- Consistent response across extreme temperature range.

- Not affected by rail currents, electromagnetic interference or RFI.

The extreme reliability of Pintsch wheel sensors is the result of decades of research and development since we started business operations during the 1950s. From the arctic to tropical conditions, our sensors provide a consistent and easily processed analog signal output. This sets a foundation for signal processing and A-to-D conversion through which axles can be accurately counted without error. Our wheel sensors are also ideal for speed measurement in yard automation projects, positive train control applications, or speed- trap service. You will find Pintsch wheel sensors operating reliably when covered in ice and snow, temporarily immersed under water, or when baking in extreme desert environments.

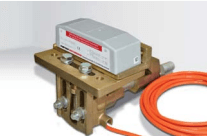

Depending on the application, a distinction is made between single wheel sensors for vehicle detection and switching tasks, and double wheel sensors for direction detection, axle counting and speed measurements.

PINTSCH offers expertise in the manufacture of wheel sensors unsurpassed by other manufacturers. The customer receives a product which has proven its high level of operational reliability in a multitude of applications, both vital and non-vital. Our sensors also serve as the heart of our ultra-reliable axle counting systems that offer a refreshing level of reliability that far exceeds that of traditional track- circuit based signal systems.

When it comes to the wheel sensors, PINTSCH TIEFENBACH provides its customers with – in every respect – customised components for evaluating and subsequent processing of the sensor signals, providing users with support when configuring and installing the components.

This involves providing special switching amplifier modules employing Euro rack technology or isolating amplifiers in compact housing configurations for installation on DIN- rails, used for processing signals.

A patented process of operation by using a constant current source allows the wheel sensors – in combination with these modules – to realize a precise and very reliable switching performance even at higher speeds and extensive cable lengths.

| Type | Single wheel sensor | Double wheel sensor | Applications | Vmax | Interface according to DIN 19234 (NAMUR) | Special feature | ||

|---|---|---|---|---|---|---|---|---|

| Train location | Direction detection | Axle counting | ||||||

| N59-1R-200-45 | X | X | ≦60 km/h | X | ||||

| NN59-1R-200-40 | X | X | ≦350 km/h | |||||

| N59-116I-200-45 | X | X | ≦350 km/h | Complete with integrated isolating amplifier | ||||

| N59-116vI-200-45 | X | X | ≦350 km/h | Integrated isolating amplifier, impulse extension 4s | ||||

| 2N59-1R-200-45 | X | X | X | X | ≦60 km/h | X | DB material number: 00117857 | |

| 2iNX59-1R-200-45 | X | X | X | X | ≦60 km/h | X | Intrinsically safe, explosion proof in accordance with Directive 94/9/EC [ATEX] | |

| 2N59-1R-200-40 | X | X | X | X | ≦350 km/h | |||

| 2N59-1R-400RE-40 | X | X | X | X | ≦350 km/h | Only available with PINTSCH TIEFENBACH axle counting systems | ||

.png?width=1920&length=1920&name=wheel-pdf-img%20(1).png)