Pintsch Shove-Light System | Train Railway safety Systems

The Pintsch Shove-Light System is the ideal solution for rail yards and industrial facilities seeking to limit injuries and prevent derailments. This system can limit the need for employees to ride a string of cars, and it also eliminates the guess work associated with remote-control operations or the staging of cars in classification yards or on terminal tracks. The system is also ideal for industrial facilities at which cars must be placed adjacent to loading racks or similar facilities.

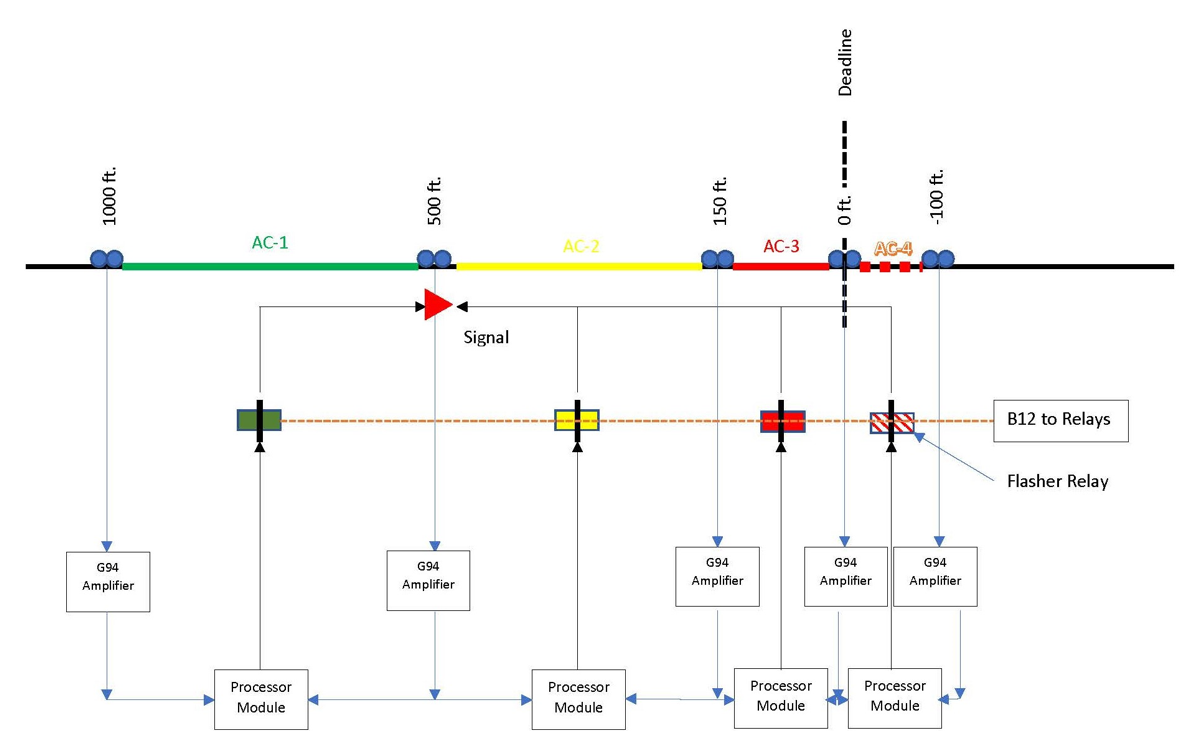

The Pintsch Shove-Light System works on a rather simple but effective principle. Examining the diagram below, one will see a typical example of this signal system designed for a class one railroad:

One will see that the track has space of approximately 1000 feet (305 meters). As the first rail car passes the sensor at the 1000-foot mark, the associated signal illuminates GREEN. The signal will remain green as long as cars remain within the 500-to-1000-feet zone.

The Pintsch Annunciator System is ideal for both large industrial facilities with dispersed rail infrastructure and smaller facilities that are not always staffed, such as remote agricultural facilities.

As additional cars are moved into the space, the signal will remain green until one or more cars reaches the 500-foot mark, at which point the signal turns YELLOW. This indicates that the string of cars has now reached the 500 feet (152 meters) mark..

Eventually, when only 150 feet of space remains, the signal will illuminate RED. This notifies the engineer or remote-control operator that he is approaching the limit of the available space.

In this scenario, a safety zone is delimited by a defined deadline. If a car should penetrate the safety zone behind the deadline, the signal will exhibit a “FLASHING RED” aspect to warn the operator that the string of cars has penetrated the safety buffer zone.

The distances and sequence can, of course, be adjusted to accommodate any yard configuration.

The system is built around the Pintsch MC6 technology, which is in widespread use on Class One railroads throughout the United States.

Pintsch signal engineers will work with rail operations to determine the best configuration for the system. As with all Pintsch signal systems, the installation work can be performed as a turn-key system by Pintsch, or Pintsch can provide the necessary technical advice to allow for in-house system construction.

Contact Pintsch North America today to discuss your requirements.